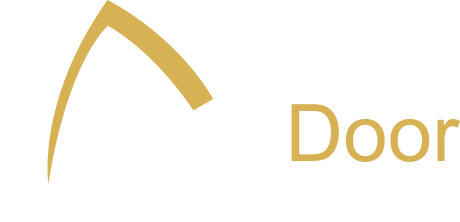

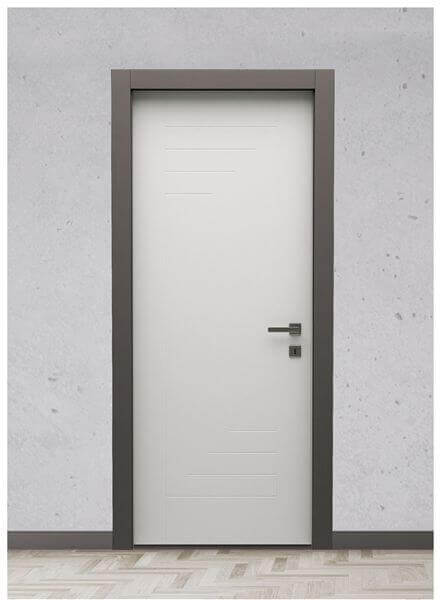

There is MDF on both surfaces of the lacquered doors, with a thickness that varies depending on the depth of the requested pattern. We recommend that the MDF used here be at least 6 mm thick. Door patterns are created by drawing them on the CNC machine on the MDF surface. The ability to draw all kinds of patterns is one of the most important features of lacquered doors. Its surface is painted with a polyurethane-based paint called Lacquer Paint. It takes its name from here.

What is a Lacquered Door?

How Are Lacquered Doors Produced?

The interior system of lacquered doors has similar features to the interior system of other door types, but is produced more fully. The first step in the production process of these doors is to create a frame called spar in the size of the requested door. Seren is a door frame made of real solid wood. After this frame is produced, the MDF that will fit on both surfaces is cut and the desired pattern is drawn on the surface on the CNC machine. Then, the MDF, which is filled inside the wooden frame and prepared for both surfaces, is pressed into the frame. After this stage, the raw version of the lacquered door will be ready.

After the raw version of the door is pressed and rested, it is now ready for painting. During the painting phase, the doors go through 5 stages. If we explain the stages in order, in the first stage, the surface of the door, which is ready in raw form, is sanded. Then, a primer is applied to the surface of the door. After the primer is applied, it is checked whether there is any roughness on the surface and the door surface is sanded again. After the sanding process is completed, the first coat of paint is applied and dried. Finally, the final coat of paint is applied and dried again. Then the door is left to rest for 2 days. After the resting period is over, it is ready for assembly. Primers and paints applied to the surface are Polyurethane based.

There are two different types of lacquered door frames. One is an MDF case whose interior and exterior are completely MDF, and the other is a type of case called Sandwich. The surface of the sandwich case is also MDF, but unlike the MDF case, there is solid wood on the inside of the case. While producing the sandwich case, MDF is pressed on both surfaces of the solid wood used inside. Moldings are always made of MDF. The painting process on the frame and moldings is exactly the same as on the sash.

What are the Features of Lacquered Doors?

Lacquered doors are high quality room doors on which a wide variety of patterns can be drawn. It achieves its high quality thanks to the materials used on the interior and the paint used on the surface. The door has MDF on both sides. Patterns are drawn on this MDF. The ability to make any desired design on the door is among the reasons why these doors are most preferred.

Lacquered doors are very solid doors. It has extra resistance to impacts compared to other types. They do not get damaged easily. Even if they are damaged, they can be easily renewed thanks to their repairability. In other words, even if very deep scratches appear on the surface of the door, they can be made new again by filling them with primer and painting them.

Lacquered doors have a much more flashy and stylish appearance than other door types. Its surface is smooth. The paint has matte and glossy options. However, matte colors are generally preferred. They can be produced in all kinds of colors. For this reason, its color can be changed later.